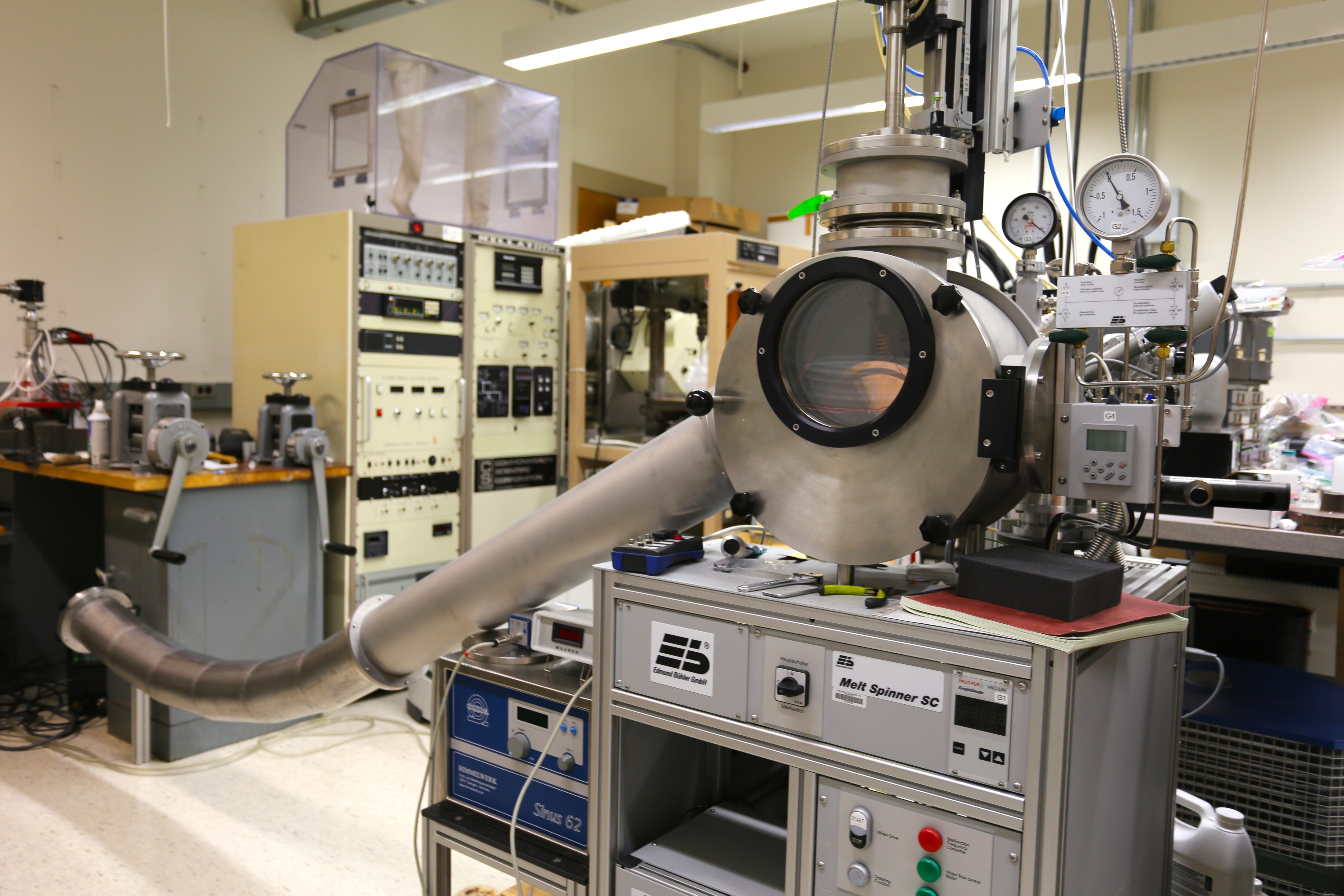

Melt Spinner SC

Melt Spinner SC is built for Laboratory scale system for max. 5 or 10 g/sample per run. Copper spinning wheel is 200 mm in diameter, complete system consisting of a high vacuum chamber, rack system, adequate high vacuum pumping system (including turbo molecular or diffusion pump), and RF generator (different models available, 5 - 6 kW). This machine is used for thin foil production by adjusting the wheel speed and the crucible's position. The width of ribbons is roughly 1 - 10 mm and the generator supply is 400 V, 3-ph, 50/60 Hz (generator); 230 V, 50/60 Hz (melt spinner).

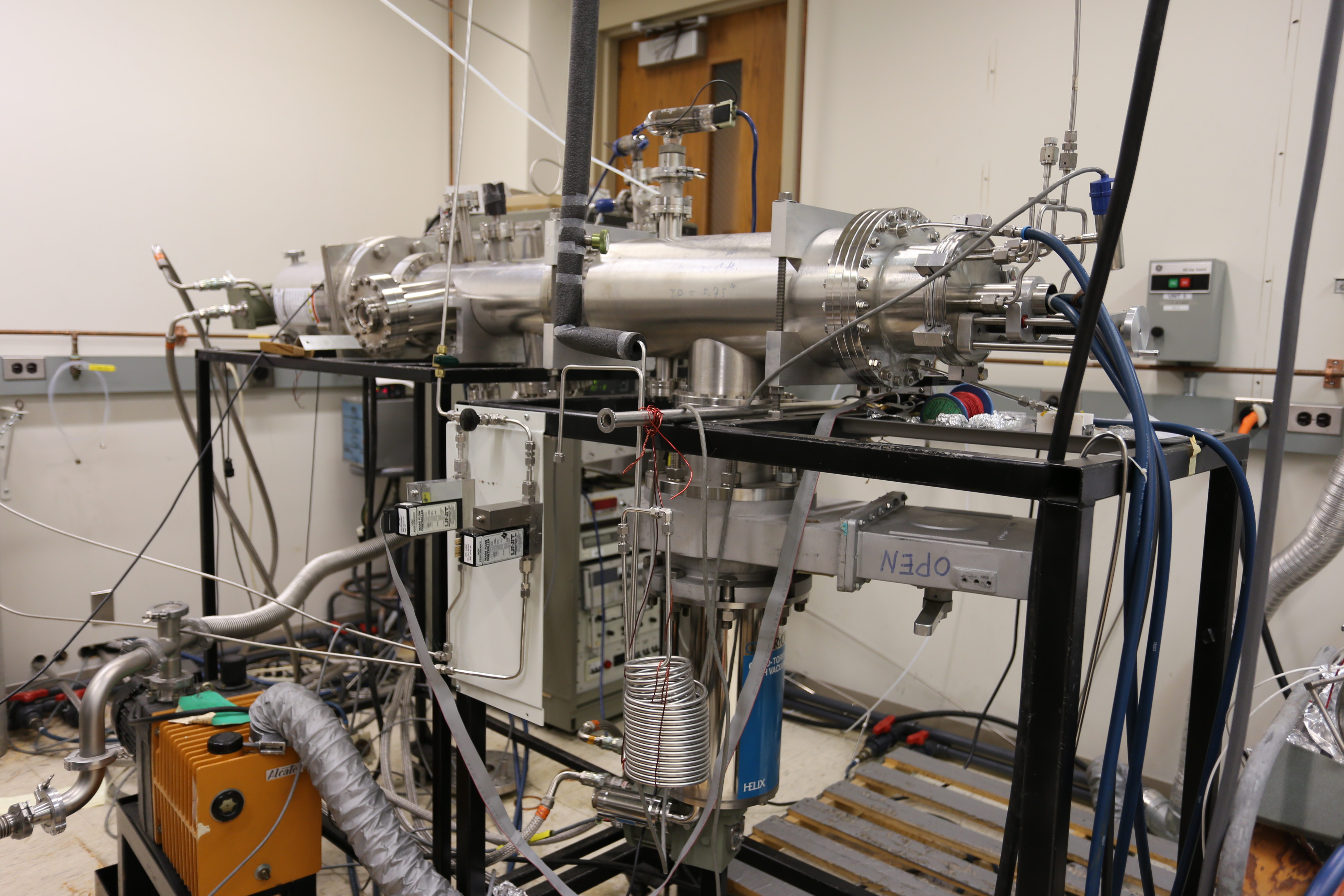

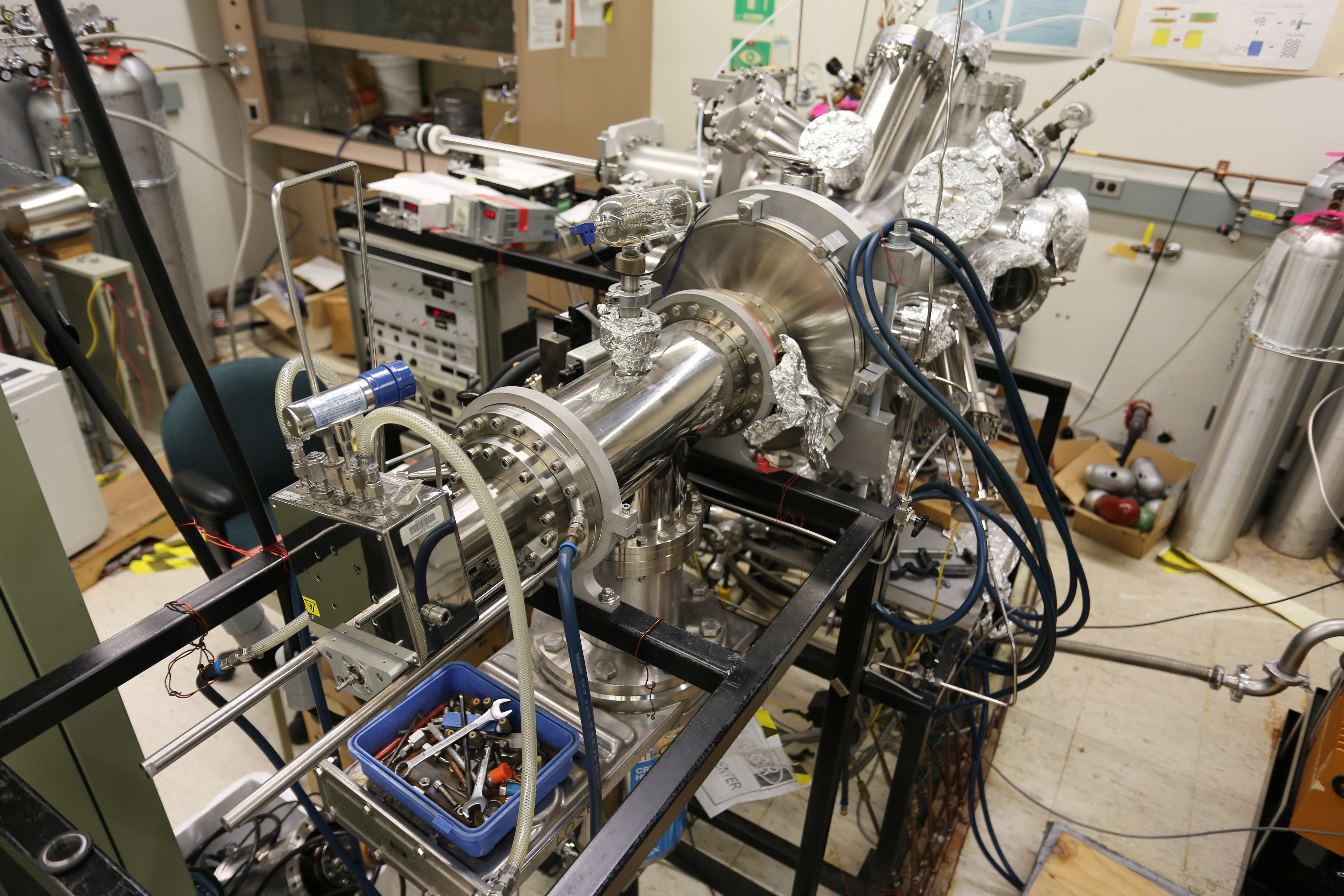

Gas-phase Condensation System - 1

This is a gas-phase condensation system used to prepare nanoparticles. This system contains a sputtering source chamber and a deposition chamber. There is a pressure differential between the two chambers to make sure the nanoparticles could fly from the source chamber to the deposition chamber. High purity metal planner target like iron is used for the sputtering. And the sputtered atoms nucleate and then grow into nanoparticles. The fabricated nanoparticles have different shapes like cubic or spherical. Nanoparticles can also show stable phase and meta-stable phase by controlling the sputtering parameters such as body-centered cubic (bcc) Fe (stable phase) and body-centered tetragonal (bct) Fe (meta-stable phase). Nanoparticles prepared by the gas-phase condensation system have clean surface because all the synthesizing processes are in a high vacuum condition, which is suitable for fundamental study and applications requiring clean surface like bio-sensing. The system also has some matrix guns which are used to deposit thin films. In this system, both nanoparticle and thin films could be generated. Thus, nanocomposite with nanoparticle and thin film matrix could be made to investigate the interactions between nanoparticles and matrix materials such as the exchange-spring interaction between hard magnetic phase and soft magnetic phase.

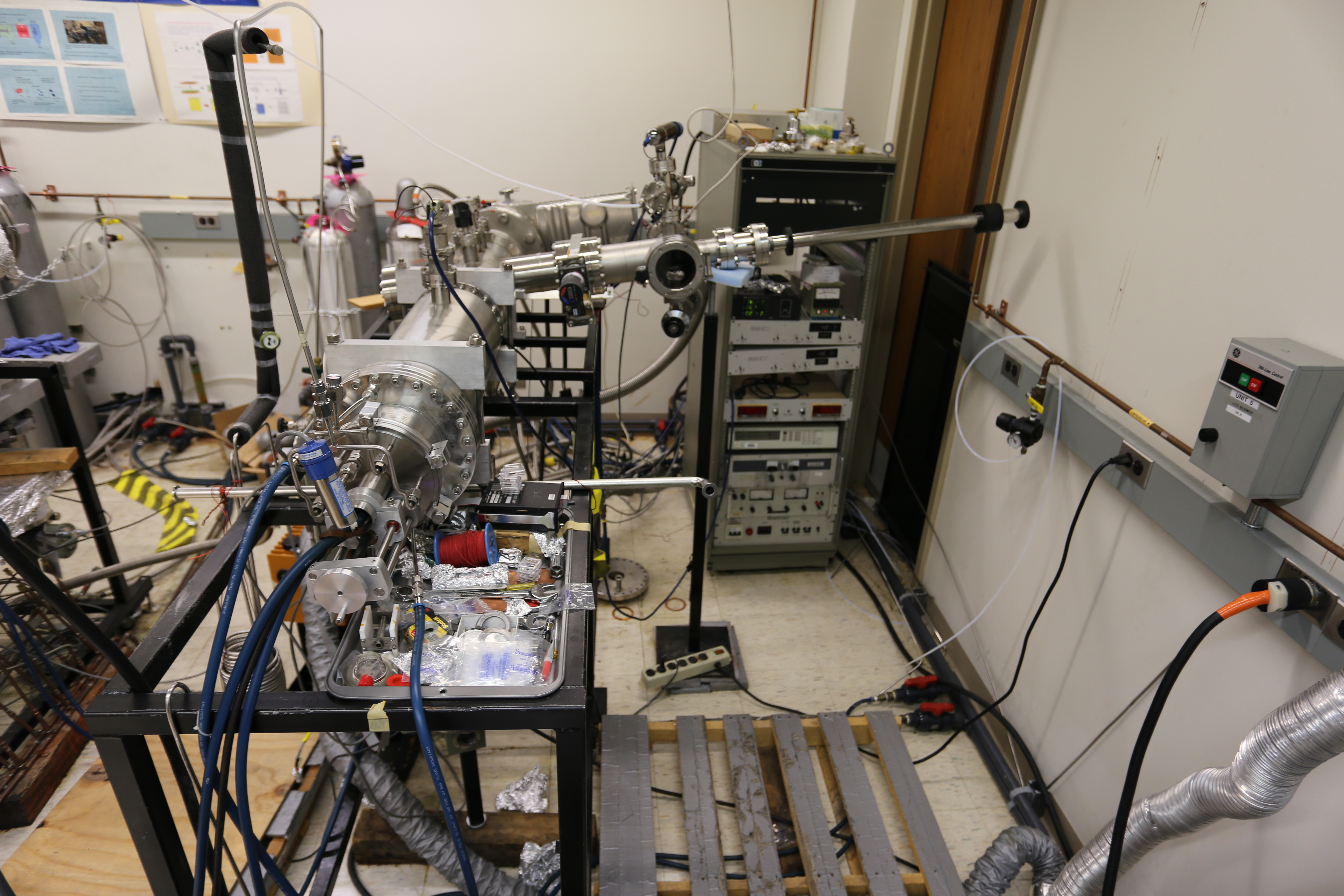

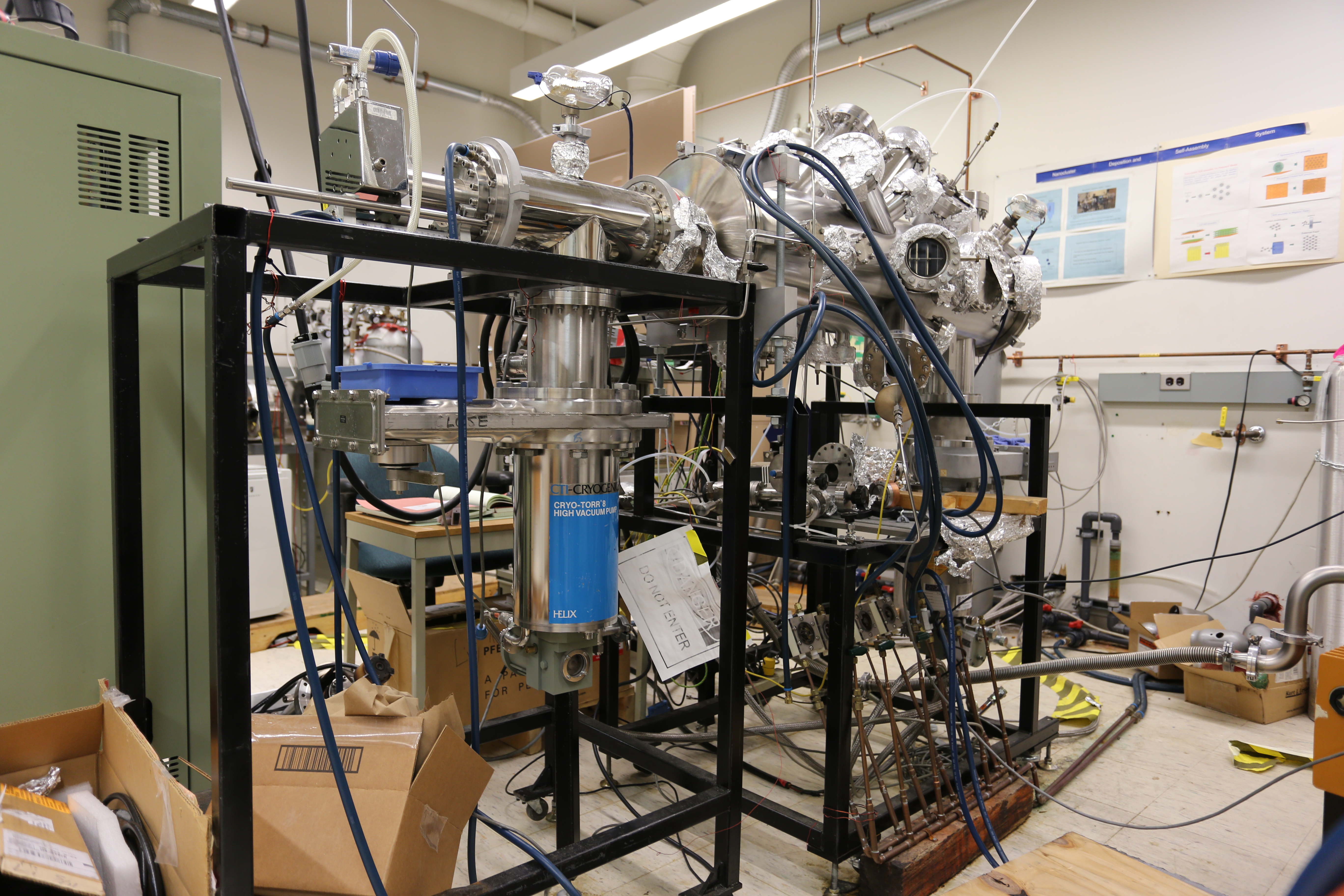

Gas-phase Condensation System - 2